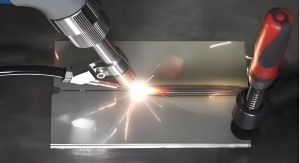

Tšimong ea kajeno e tsoetseng pele ea ho etsa kajeno,Mochini o khaphatsehang oa sefofane o ile oa tsamaeaE fetoha khetho e tsebahalang hore ho hlapaola liphapang ka ts'ebetso ea eona e ntle le ea bohlokoa. Joale, ho na le menyetla efe e makatsang? Ha re bolileng.

I. LITLHAKISO TSA BOPHELO BA LINAKO TSA BOPHELO BA PUA HO HLOMPILED

- Matla a Laser: Lenaneo le tloaelehileng la laser le pakeng tsa 800W - 2000W, le ka kopanyang litlhoko tsa boima ba bophahamo le lisebelisoa tse fapaneng tse fapaneng.

- Lebelo la Welding: Lebelo la bona la Welding le ka fihla 5m / mets - 10m / min, e ntlafatsa katleho ea tlhahiso le ho khutsufatsa potoloho ea tlhahiso.

- Sebaka sa tšollo: Bophahamo ba eona bo pakeng tsa 0.2mm - 2mm. Taolo e nepahetseng ea sebaka e ka fihlela lintlha tse ntle le tse phahameng.

- Khafetsa ts'ebetso: Khafetsa ts'ebetso ea ts'ebetso ke 20khz - 50khz. Ts'ebetso ea khafetsa e tiisa tsoelo-pele le botsitso ba ts'ebetso ea metlae.

- Boima ba lisebelisoa: Boima ba e ka bang 20kg - 60kg e thusa okitara ho ts'oara le ho sebelisana habonolo le maemo a fapaneng a ho hlapanya.

- Litlhaloso tsa boholo: Moralo o kopanetsoeng ka bolelele ba 50cm - 80cm, bophara ba 40cm - 60cm ha e sebetse libakeng tse fapaneng tsa ho sebetsa libakeng tse fapaneng tse sebetsang.

- Litlhokahalo tsa motlakase: Hangata, e tšehetsa ho kenya letsoho ka 220v kapa 380v, e tloaela tikoloho e fapaneng ea ho fana ka tikoloho ea lipolotiki tsa Power e fapaneng ea indasteri.

- Lisebelisoa tse sebetsang tse sebetsang: E loketse lisebelisoa tse fapaneng tsa tšepe tse kang tšepe e se nang mabe, aluminum allows.

- Tlhahiso ea lisebelisoa tsa lisebelisoa tsa lisebelisoa: Ha e bapisoa le lisebelisoa tsa Welding tsa setso, e fokotsehile haholo, 'me e ka boloka litšenyehelo tse ngata tsa likhoebo tsa nako e telele.

II. Sesebelisoa se matla sa ho ntlafatsa katleho ea mosebetsi

TheMochini o khaphatsehang oa sefofane o ile oa tsamaeae na le katleho e ntlafalitsoeng haholo ea mosebetsi ka ho sebetsana le boemo ba eona bo ikhethang. Mohlala, ka har'a lisebelisoa tsa likoloi tsa likoloi, ho nka lihora tse 'maloa ho phethela mekhoa e mengata ka mekhoa e meholo ea setso. Leha ho le joalo, ka mor'a ho amohela mochini oa weli o hahiloeng ka letsoho o hahiloeng ka sefofane, nako ea ho sebelisa chelete e khutsufatsoa ho mashome a mabeli. Lebelo la ho sebelisa ka potlako le boleng bo botle ka ho fetisisa bo eketsehile haholo nako e le 'ngoe ea ho feta' me u fokotse nako le lisebelisoa tse sentsoeng ka lebaka la ntlafatso.

III. Fokotsa litšenyehelo haholo

- N LITLHAKISO TSA BOPHELO TSE KHOLO TSE FUMANENG LITSELA TSE KHOLO TSE KHOLO LE LITLHAKISO TSA BOPHELO TSA BOPHELO LE LITLHAKISO TSE KHOLO TSE FUMANANG MOSA OA HO BONAHALA, 'me tšebeliso ea nako e telele e ka boloka litšenyehelo tse kholo tsa motlakase.

- In terms of material cost, precise welding control reduces material loss during the welding process, improves material utilization, and reduces the purchase cost of raw materials.

- Litšenyehelo tsa tlhokomelo le tsona li fokotsehile haholo. Ts'ebetso ea eona e tsitsitseng e sebetsang le sebopeho se bonolo se fokotsa khafetsa le ho hloka lisebelisoa tsa lisebelisoa le ho lokise.

IV. Bonolo bo sa fetoheng ts'ebetsong

- Moralo oa ponahalo ea lisebelisoa ke Ergodomic, ha sebetsana le motho ea phutholohe, ebile ha ho bonolo ho tepella ts'ebetsong ea nako e telele.

- Sehopotso sa puisano sa motho se bonolo ebile se totobetse, 'me likonopo tsa ts'ebetso li hlakile ebile ho bonolo ho li utloisisa, ho lumella basebetsi ho qala kapele.

- Ts'ebetso ea paramente e bohlale e nolofalletsa basebetsi ho lokisa liparamente tse ngata ho latela mesebetsi e fapaneng ea ho bota.

Qetellong,Mochini o khaphatsehang oa sefofane o ile oa tsamaeao bontšitse menyetla ea bohlokoa tšimong ea lienndaria le litlhaloso tsa eona tse matla tsa mahlale, ts'ebetso e ntle ea ho sebetsa, mekhoa e makatsang le mekhoa e metle ea ho sebetsa le mekhoa e hlollang. Ebang ke ho ntlafatsa ts'ebetso ea tlhahiso, ho fokotsa litšenyehelo tsa tlhahiso, kapa ho fana ka boiphihlelo bo bonolo, ke khetho e ntle. Ho lumeloa hore nakong e tlang, e tla phetha karolo ea bohlokoa masimong a mangata mme e khothalletsa ho ntšoa 'me u tsoela pele ho ntšetsa pele indasteri ea tlhahiso.

Nako ea poso: Jul-09-2024