Likhethong tsa sejoale-joale, ts'ebeliso ea2000W FABLDES ROWND WADingBakeng sa litsela tsa ho ithuta tsa aluminiumum e ntse e ata haholo. Leha ho le joalo, ho netefatsa hore boleng bo renngoeng le polokeho, litaba tse latelang tse latelang li hloka ho hlokometsoe.

1. Phekolo ea pele pele u soma

Filimi ea oxide e holim 'a tšepe ea aluminium e ka ama boleng ba tsela. Ho kalafo ka holimo ho tlameha ho etsoa ho tlosa filimi ea oxide, matšoenyeho a oli le litlolo tse ling. Ha likarolo tse ling tsa likoloi li ile tsa sebelisana le mojaki, ka lebaka la ho se tsotelle ha tšoaro e kholo, palo e kholo ea li-pares le mapetso a tšoanelehang li lelekoa. Kamora ho ntlafatsa ts'ebetso ea kalafo, sekhahla sa lipalo se nyolohela ho feta 95%.

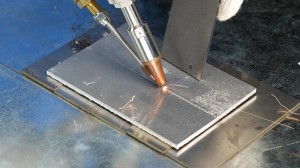

2. Khetho ea litekanyetso tse loketseng tsa welding

Literaka tse jang Stameter tse kang matla a laser, lebelo le thata le ho tsepamisa maikutlo a bohlokoa haholo. Bakeng sa li-aluminium plates tse nang le botenya ba 2 - 3mm, matla a 1500 - 1800W e loketse haholo; Bakeng sa ba nang le bophara ba 3 - 5mm, 1800 - 2000w e loketse. Lebelo la welding le lokela ho tsamaisana le matla. Mohlala, ha matla a 1800w, lebelo la 5 - 7mm / s e loketse. Boemo ba sepheo le bona bo ama phello e itseng. Tsepamisa mohopolo bakeng sa lipolanete tse tšesaane li holim 'a bona bakeng sa lipotoloho tse teteaneng, e hloka ho teba ka hare.

3. Taolo ea ho kenya mocheso

Tšepe ea aluminium e na le tšebelisano e tukang 'me e na le tahlehelo ea mocheso, e amang metsi a mangata le matla a mangata. Taolo e nepahetseng ea ho kenya maikutlo ho hlokahala. Ka mohlala, ha khoebo e sa sebetseng ea Aerospace e ile ea sebelisa likarolo tsa aluminium, ho laola likhomo ho ile ha etsa hore seretse se sa felloe ke sesoleng. Bothata bo ile ba rarolloa kamora ho ntlafatsa tšebetso.

4. Sepehelo sa khase e sirelelitsoeng

Khase e loketseng ea ho silafatsa khase e ka thibela oxidation e ngata le litšeho. Argon, Herium kapa motsoako oa tsona o sebelisoa hangata, 'me tekanyo ea ho phalla le tsela e meholo e lokela ho lokisoa hantle. Patlisiso e bonts'a hore sekhahla sa ho phalla ha Argon ho tloha ho 15 - 20 l / min le tataiso e loketseng ea lipalesa li ka fokotsa pelo.

Nakong e tlang, ho lebelletsoe hore lisebelisoa tsa metlae tse matla li tla hlaha le lisebelisoa tsa tšepe tse bohlale le ho feta le thepa e mecha le lisebelisoa tse ncha le tsona li tla khothaletsa ts'ebeliso e kholo. Qetellong, ke ka ho latela mehato ena ea ho ba hlokolosi, boiphihlelo bo bokellanang le ho ntlafatsa ts'ebetso ea Wiskation ho ka kenya letsoho ho nts'etsopele ea indasteri ea tlhahiso.

Nako ea poso: Jul-12-2024